The importance of maintaining proper sealant joints

What will happen if you forget to shut the windows of your home on a stormy day?

The home will be exposed to unwanted dirt & dust, damaging your property and leading to enormous repairs.

Sounds bad, right? Because the repair costs would not have occurred if you had remembered to lock the windows.

A similar scenario can occur if the joints of your building are not secured with silicone sealant. Skipping the application of silicone sealant on joints can lead to many problems that will potentially damage the structure of the building.

The most common problems that arise due to the absence of silicone sealant in joints are leakage, cracks, and weakening of the structure.

These problems might seem little today, but they do take an unlikely turn and cause more problems such as damage to the plaster, discolouration, corrosion, etc.

The absence or improper application of silicone sealant can cost a hefty amount to the building in the future. When any construction job is undertaken, there is a comprehensive list of construction work to take care of and at times in the process, the minutest details are missed.

High-rise buildings and bungalows have thousands of lineal feet to fill in with sealant. While undertaking the job of sealing such large structures, there are chances of missing out on a couple of blind spots and gaps.

These blindspots can cause troubles like:

- Leakage

- Cracks

- Discolouration

- Corrosion

If any of the above-mentioned problems occur, the building should opt for a silicone sealant maintenance service.

The stated problems lead us to a question i.e. Do these problems only occur when the silicone sealant is not applied?

The answer is no, there are scenarios where problems like leakage and cracks occur despite the presence of silicone sealant in joints.

This happens because factors such as how you apply silicone sealant, which silicone sealant has been used, are as important as applying silicone sealant.

Even the best performing silicone sealants can fail if applied in an improper manner, used on incompatible material, and insufficient substrate preparation.

Where silicone sealant should be applied in a building?

1. Control Joints

Control joints are the space existing between two concrete slabs. This space allows the movement caused by temperature changes and other factors.

The space between concrete joints is closed with silicone sealant to retain flexibility and prevent the joints from being infiltrated by air, water, and other harmful chemicals.

2. Window/door-to-wall connection

While installing a window or door frame minute space appears between the door/ window frame to the wall.

The appearing gap needs to be sealed by silicone sealant so that the room is completely enclosed, eliminating the possibility of leakages.

3. Precast

Precast is a concrete structure manufactured in construction factories. These concrete slabs are cured into a particular shape. To derive the desired shape concrete is poured into a mould. Rectangle & square are the two most popular precast shapes.

Precast is directly installed at the site of construction. The installation is then secured by an airtight and watertight seal to give it resistance against severe weather.

4. Foundation

The strength of any small or big construction depends on its foundation. Stronger the foundation, the better the strength of the building.

Thus, it becomes extremely important to choose the right construction grade silicone sealant for sealing joints of the foundation.

5. EIFS & Facade

The entrance of the building is the face of it. Architects and engineers design it to be unique, facade design requires other elements than concrete like ACP panels, glass and others.

Such material is adjoined with concrete structure using a silicone sealant. Because silicone sealant transitions to dissimilar materials.

Looking back at the mentioned points, you will realize that sealant is the integral part, base, and finisher of any construction job. These applications themselves justify the importance of silicone sealant for building joints.

Thus it is of utmost importance to seal the deal with construction units, once the sealing process is undertaken, it is also necessary to do regular sealant maintenance checks.

How to identify existing sealant issues in the structure?

Even though the sealant is applied in small quantities and is difficult to spot, if looked closely, the naked eye can spot the following issues in the joints if the sealant application is compromised.

Cracking: Even though silicone sealants have a decade & more of longevity, it is important to keep a check on them as over the years because of movement and temperature, cracks might start appearing within the sealant.

Peeling: If during the initial construction process, the applied sealant is of poor adhesion or compatibility, then the silicone sealant starts peeling off allowing the ingress of moisture. That will further damage the construction.

No Sealant: At times when the construction work is undertaken in haste, one of the most important aspects of construction i.e. application of silicone sealant is missed.

How to resolve silicone sealant issues on joints?

The resolution process and practice should be chosen after studying and identifying the silicone sealant issue.

When a building goes under the silicone sealant maintenance process, it is advised to consult a trusted silicone sealant manufacturer to decide which silicone sealant to use, should it be the same as applied once? Or another sealant that is compatible with the previous one? Choosing the right silicone sealant eliminates half of the problem.

Scenario 1

If the silicone sealant is intact except for a little damage on the surface, the following steps must be followed:

1. Existing sealant surface should be thoroughly cleaned using the two-rag method and isopropyl alcohol for silicone sealant.

2. Once the sealant is cleaned, let the surface dry for a well and then start applying silicone sealant to the joint. Let it dry until cured & voila the joints are new again.

Scenario 2

If the silicone sealant has ceased to function then:

1. Start with removing the damaged sealant

2. Clean and pre-prepare the substrate as advised on the silicone sealant manual that is going to be used.

3. Apply the silicone sealant and let it dry.

4. Once applied and dried, check if it is intact and not soft.

Silicone Sealant To Use For Joint Maintenance:

Out of the vast category of silicone sealants used for outdoor application, choosing a silicone sealant from the following categories will be the perfect choice:

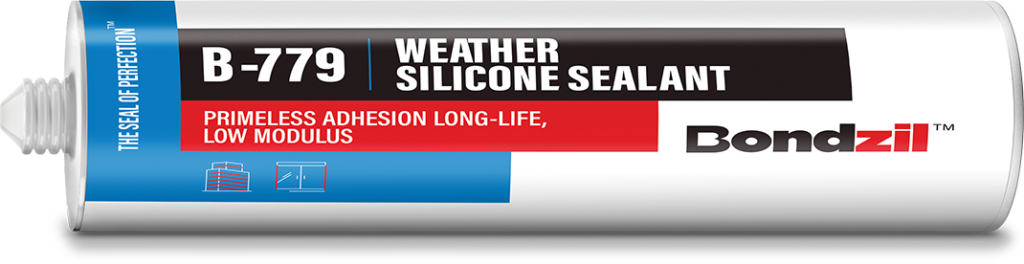

1. Weather Silicone Sealants

This silicone sealant category is developed for showcasing undefeatable strength in any weather. The seal produced by weather silicone sealant is resistant to UV Rays, storm, and water.

2. HYB Silicone Sealants

HYB category of silicone sealant is developed with SMP (Silyl-modified polymers) Technology that gives the seal an unwavering strength and flexibility that exceeds its longevity than other sealants.

The task of overseeing building maintenance is a huge responsibility. And in the process of maintenance sealants are often disregarded, but they are the most crucial part of building envelope, facade and joints. Thus silicone sealant maintenance should be prioritized.